Project Overview

This project represents a comprehensive exploration of hardware fabrication, electronics integration, and artificial intelligence deployment. I built a custom fixed-wing drone from scratch, 3D printing all structural components and hand-soldering every electronic connection. The ultimate goal is to deploy a locally-run AI system capable of real-time computer vision for gait analysis and person re-identification.

Technical Implementation

🖨️ 3D Design & Fabrication

Printed all airframe components including fuselage, wings, and control surfaces. Optimized weight distribution and structural integrity for flight performance.

⚡ Electronics Integration

Hand-soldered all flight controller connections, ESCs, servos, and power distribution systems. Integrated camera modules and communication systems for telemetry.

🤖 AI & Computer Vision

Developing edge AI deployment for real-time gait pattern analysis. Implementing person re-identification algorithms optimized for embedded systems and aerial perspectives.

🎮 Flight Systems

Configured flight controller firmware, calibrated sensors, and programmed autonomous flight modes. Integrated RC control systems with telemetry feedback.

Project Gallery

3D printed fuselage

Full assembly with wings, electronics bay, and RC components laid out

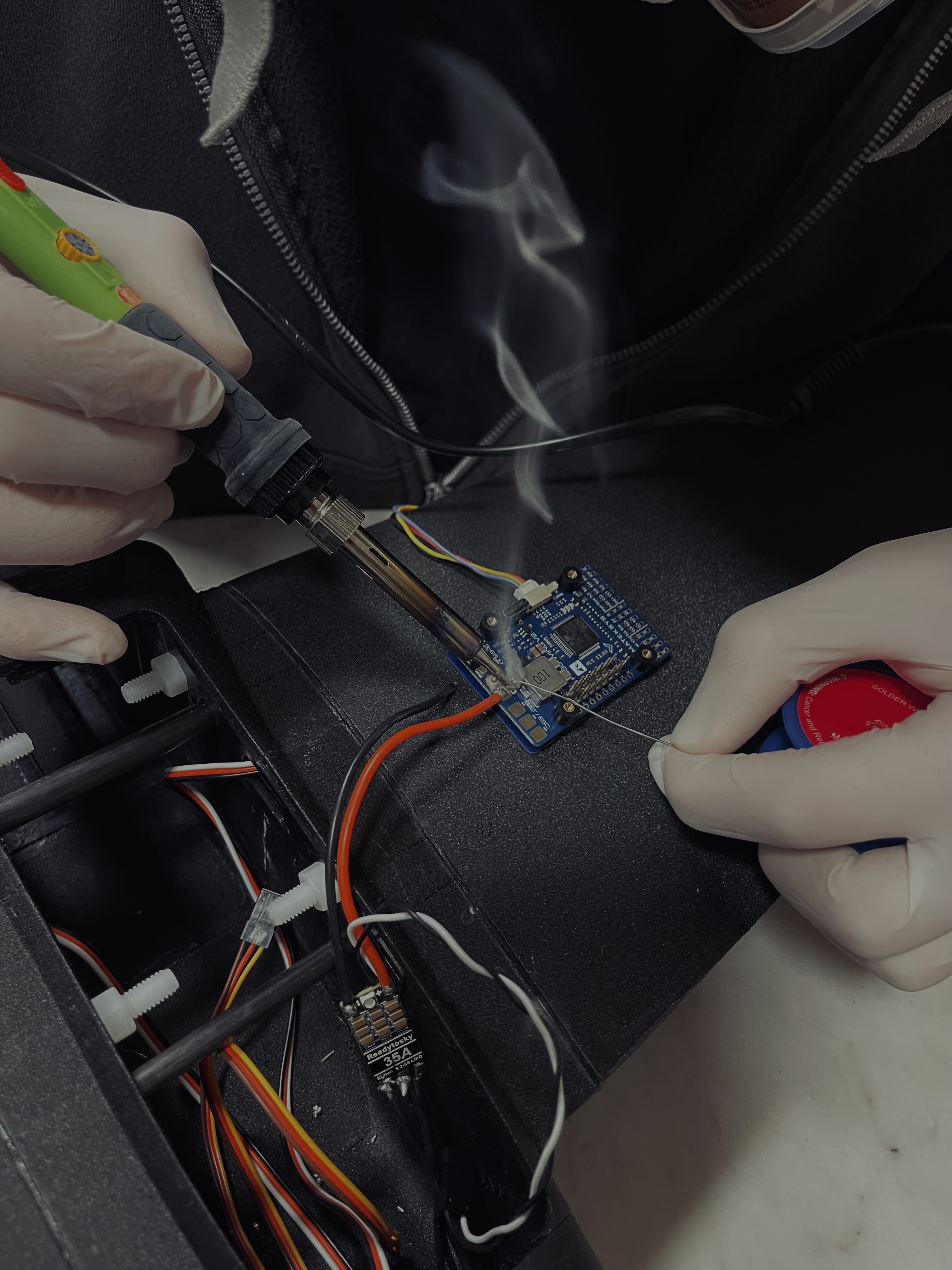

Assembelling fixed-wing drone with flight controller

Hand-soldering flight controller connections with precision and proper technique

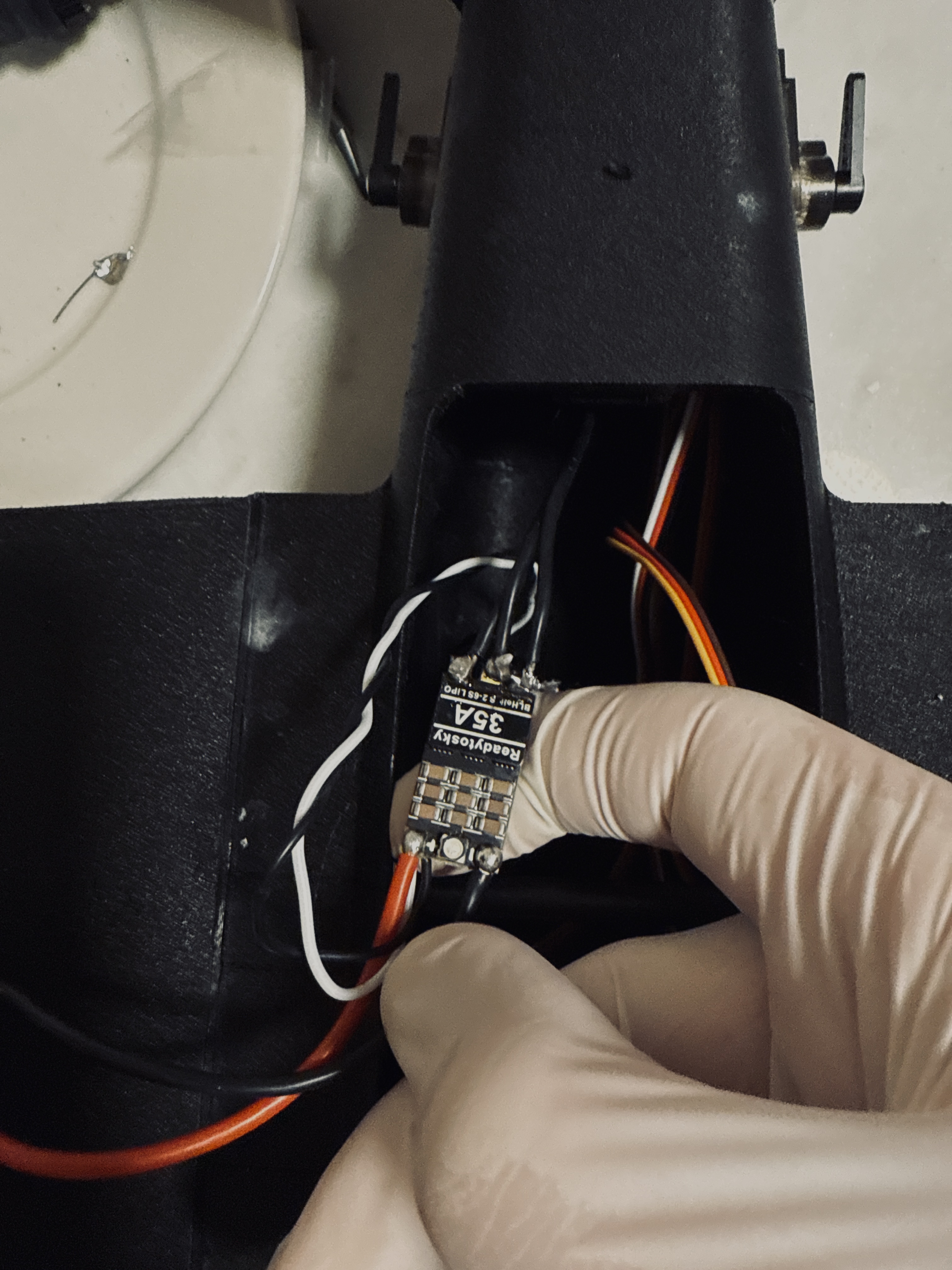

ESC mounted inside fuselage with clean wire management and secure connections

Almost complete version of fixed wing drone

Build Process

Phase 1: Fabrication

3D printed all components using optimized print settings for strength-to-weight ratio. Post-processed parts for smooth surfaces and proper fit.

Phase 2: Electronics Assembly

Soldered flight controller, ESCs, and all sensor connections. Implemented proper wire management to ensure reliable operation.

Phase 3: System Integration

Mounted all electronics within the airframe, balanced the aircraft, and calibrated sensors. Configured flight controller parameters and tested control surfaces.

Phase 4: AI Development (In Progress)

Training computer vision models for gait analysis and person re-identification. Optimizing inference for edge deployment on limited computational resources.

Skills Developed

- 3D Printing: Using slicers such as Bambu Lab to properly configure prints

- Soldering & Electronics: Hand-assembled intricate electronic systems with proper technique and quality control

- Embedded Systems: Configured flight controllers and sensor integration

- Machine Learning: Developed and optimized neural networks for edge deployment

- Computer Vision: Implemented gait analysis algorithms for person re-identification

- System Integration: Combined mechanical, electrical, and software components into a cohesive platform

- Problem Solving: Debugged complex hardware-software interactions and overcome integration challenges

- Safety Protocols: Followed proper procedures for battery handling, soldering, and testing

Technical Challenges

Weight Optimization

Balancing structural integrity with minimal weight required careful material selection. Each component was evaluated for its weight contribution versus functional necessity.

Power Management

Designing an efficient power distribution system to support flight systems, camera, and AI processing while maintaining flight time and safety margins.

AI Edge Deployment

Optimizing computer vision models to run on embedded hardware with limited computational power while maintaining real-time performance for aerial surveillance applications.

Future Development Goals

Autonomous Navigation: Implement GPS waypoint navigation and obstacle avoidance capabilities

Real-Time Tracking: Deploy trained AI models for live gait-based person tracking and re-identification

Data Pipeline: Develop efficient data collection and processing pipeline for model improvement

Extended Range: Optimize power systems for longer flight times and greater operational range

Telemetry Dashboard: Create ground station software for real-time monitoring and control

Technologies & Tools

Hardware: 3D-printed airframe, Flight controller, ESCs, Brushless motors, LiPo batteries, Camera modules, RC receiver/transmitter

Software: Flight controller firmware, Python for AI development, TensorFlow/PyTorch for model training, OpenCV for computer vision

Tools: Soldering station, 3D printer, CAD software

← Back to Portfolio